*Each section involves practice of calculation and application of geometric tolerances.

Engineering Drawing and GD&T

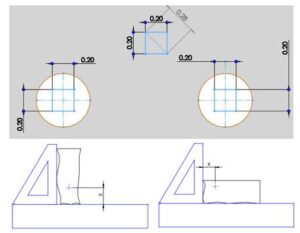

- Engineering Drawings

- Introduction to Dimensioning

- Dimensioning Rules

- Co-Ordinate Dimensioning System

- Geometric Dimensioning and Tolerancing system Myths in GD&T

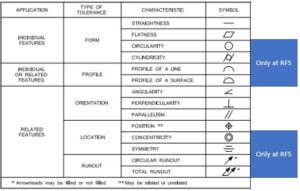

Definitions and Symbols

Rules and Different concepts of GD&T

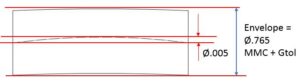

- Limit of size

- Brief of Rule#1

- Brief of Rule#2

- Application of MMC and

- Bonus Tolerance

Tolerance selection

From Tolerance

- How to select Form Tolerance

- Straightness tolerance

- Flatness tolerance

- Circularity

- Cylindricity tolerance

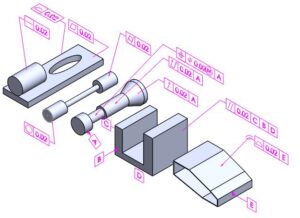

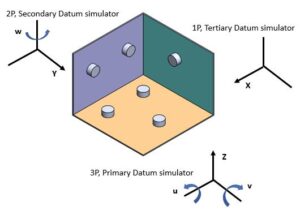

Datum selection

- How to select Datum

- Datum feature

- Datum identification

- Planar datum

- Datum feature of RMB

- Maximum Material boundary

- Least material boundary

- Datum shift

- Datum targets

- Simultaneous requirement

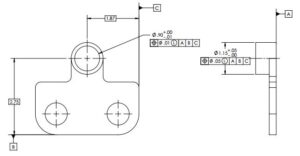

Positional Tolerance

- How to select Datum

- Tolerance of location-positional tolerance

- Positional tolerance-RFS

- Positional tolerance -MMC

- Positional tolerance-LMC

- Brief of Multiple segment and composite tolerance

- Application of projected tolerance zone

- Simultaneous requirement

- Positional coaxial control

- Concentricity

- Symmetrical relationship

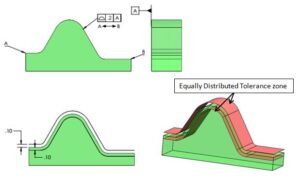

Tolerance of profile

- Profile tolerance

- Uniform profile tolerance zone

- Bilateral tolerance

- Unilateral and unequal bilateral

- All around and all over symbols

- Different tolerance for different segment of cross section

- Brief of Non uniform tolerance zone

- Brief of Composite Tolerance application

- Application of profile tolerance

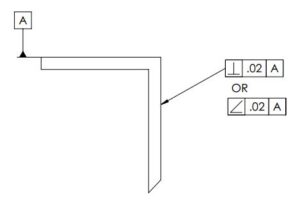

Orientation tolerance

- Orientation tolerances

- Angularity

- Parallelism

- Perpendicularity

- Tolerance zone for orientation tolerance

- Orientation tolerance @MMC modifier

- Projected tolerance

Runout tolerance

- Tolerance of Runout

- Datum section for Runout

- Circular runout

- Total runout

- Application of circular runout on a curved surface

Tolerance

- What, Why

- Limits- Fits and Tolerances

- Precision and Accuracy

- Various Fits

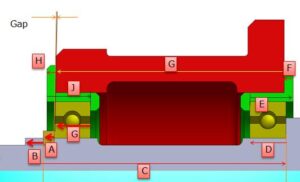

Tolerance Stack-up

- Myths in Tolerance Stack-up

- What is tolerance Stack-up Analysis?

- Why to do tolerance Stack-up Analysis?

- Benefits tolerance Stack-up Analysis

- What are the driving factors in Stack-up analysis

- Assumptions and ways of doing stack-up

- Steps to be followed

- Rules preparing Loop diagram

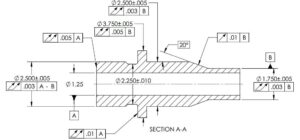

Converting all tolerancing system to equal bilateral system

Examples Practice (Part Level and Assembly Level)

Fixed and Floating Formulas and Concept

Converting GD&T to Normal ± tolerance to use in stack-up analysis

- Few terminologies (VC, RC, OB and IB, Datum shift)

- Form Tolerances – To include in Tolerance stack-up or not

- Orientation Tolerances on surface and on feature of size

- Profile (Composite tolerance effect as well)

- Positional Tolerance (Composite tolerance, when and how to include segments)

- Datum shift assumption in Tolerance Stack-up

- Runout Consideration

- Symmetry and Concentricity

Radial Tolerance Stack-up

Part With Dimension and tolerance at an angle

Statistical Tolerancing (RSS and MRSS)

Reviews

There are no reviews yet.