- Course fee Includes 6 months of membership and Telephonic Personal consultation for any Tolerance Stack-up related issue.

- For Company – Drawing review and Expert Suggestions, Design and detail engineering. Helping hand in Loop formation and reviewing stack-up analysis.

- Understanding of Basics of GD&T (Couple of hours)

- Tolerance zones, envelopes for All Geometric tolerancing.

- Rule#1

- Rule#2

- Form Tolerances – Straightness, Flatness, Circularity, Cylindricity

- Datum, 3-2-1 principle and Envelopes

- Position Tolerance

- Orientation Tolerance

- Concentricity

- Symmetricity

- Profile of a Line, Profile of a surface

- Circular and Total runout

- Tolerance

- What, Why

- Limits- Fits and Tolerances

- Precision and Accuracy

- Various Fits

- Tolerance Stack-up

- Myths in Tolerance Stack-up

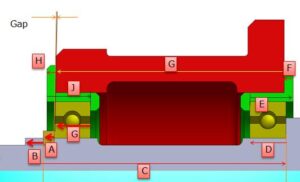

- What is tolerance Stack-up Analysis?

- Why to do tolerance Stack-up Analysis?

- Benefits tolerance Stack-up Analysis

- What are the driving factors in Stack-up analysis

- Assumptions and ways of doing stack-up

- Steps to be followed

- Rules preparing Loop diagram

- Converting all toleracing system to equal bilateral system

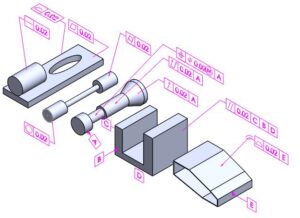

- Examples Practice (Part Level and Assembly Level)

- Fixed and Floating Formulas and Concept

- Converting GD&T to Normal ± tolerance to use in stack-up analysis

- Few terminologies (VC, RC, OB and IB, Datum shift)

- Form Tolerances – To include in Tolerance stack-up or not

- Orientation Tolerances on surface and on feature of size

- Profile (Composite tolerance effect as well)

- Positional Tolerance (Composite tolerance, when and how to include segments)

- Datum shift assumption in Tolerance Stack-up

- Runout Consideration

- Symmetry and Concentricity

- Radial Tolerance Stack-up

- Part With Dimension and tolerance at an angle

- Statistical Tolerancing (RSS and MRSS)

Reviews

There are no reviews yet.